Quality For Lamination

Inflow of Raw Material:

Upon receipt of the material at the plant, the same is tested in the in-house testing laboratory against the specified values of the mills for each parameter.

Electrical Losses of each and every coil are tested using Epstein Tester or Single Sheet Tester to verify the losses specified by the mills.

Franklin Insulation Resistance Test is performed on the material to ensure its surface insulation is in-lieu with customer requirements

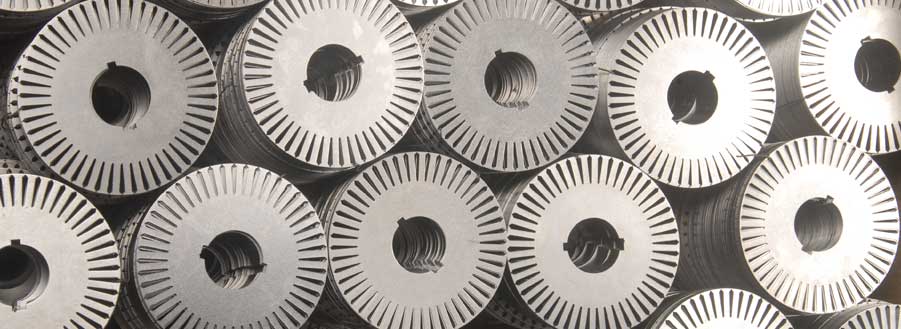

PROCESS TESTING:

First Piece-setup Approval: Prior to commencement of slitting, cropping or packaging first-piece setup approval in well documented formats.

In-Process Inspection Get photographs

- Raw Material Slitting: Width, Burr, Waviness, Camber, Appearances.

- Cropping Line: Dimensions and parameters as per major International Standards or in accordance with customer requirements.

- Packing Stage: Dimensions, watt loss, surface insulation, stack, packing quality and labeling are checked before dispatch.

Dispatch Stage:

Each and every order processed has a unique tracking code allowing the final product to be tracked right up to its mother coil. Before shipment the packing quality are checked to ensure hassle free unloading at customer’s work place.

|